Key Takeaways

- Piping supply is adapting rapidly to changing industry demands, sustainability, and new technologies.

- Material selection and proper sizing are crucial for system performance and safety.

- Supply chain challenges necessitate proactive planning and supplier relationships.

- Stay updated with new standards and innovations to ensure efficiency and compliance.

- Visit resources like how digital transformation is impacting the global pipe industry for insights.

- Maintaining an environmentally-conscious approach gives businesses a competitive edge.

- Ongoing education and training help teams keep up with new best practices and products.

- Consider recent construction and supply news when planning large projects to avoid costly delays.

Introduction to Piping Supply Challenges and Opportunities

Piping supply forms the critical framework for a wide range of industries, including construction, manufacturing, energy, and residential plumbing. As project scopes grow and the need for resilience intensifies, businesses face new complexities in balancing cost, efficiency, and future-proofing their operations. Sourcing and tracking high-quality piping products has become a much more dynamic process due to increasing demand and evolving regulations. Staying ahead in piping supply demands a focus on both innovation and reliability. Companies and contractors must now factor in material shortages, fluctuating prices, and environmental goals alongside technical considerations. Adapting to these trends and weaving best practices into procurement and inventory management is the key to ensuring project success and operational continuity.

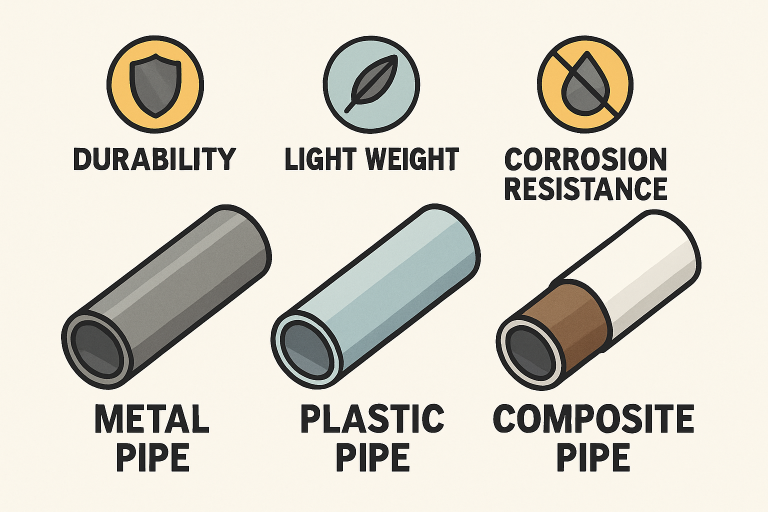

The Role of Materials in Modern Piping Systems

The choices made in pipe materials drive system longevity, safety, and overall project value. Pipe selections—ranging from traditional options such as steel and copper to modern plastics and advanced composites—directly affect performance under different environmental conditions. Each material comes with its own profile of durability, cost, and installation complexity. In recent years, there has been a surge in demand for materials that offer corrosion resistance, are lightweight, and are easy to install. Today’s decision-makers must balance practical concerns like local availability and cost with longer-term aims, including sustainability and maintenance requirements. As regulatory pressure for eco-friendly solutions grows, many teams are turning to PVC, PEX, and recycled composites for their ability to reduce waste, streamline installation, and minimize environmental footprints.

Size, Scale, and Design Considerations

Piping system performance hinges on the correct sizing and thoughtful system design. Undersized piping can lead to pressure drops, system noise, and wear, while oversizing may result in wasted resources and increased project costs. Engineers use advanced modeling tools and simulation software to analyze system needs and design scalable solutions suited for both present requirements and future expansions. Compatibility with existing infrastructure is another determinant of success, requiring careful calculations on flow, temperature, and system dynamics. Engaging experts early in the design process and adhering to industry best practices reduces risk and helps ensure regulatory compliance, efficiency, and safety.

Supply Chain Hurdles and Solutions

The past several years have shown just how fragile global piping supply chains can be, with lead times and prices fluctuating due to demand shocks and international disruptions. Proactive purchasing strategies, establishing relationships with multiple vetted suppliers, and ongoing market research are now standard approaches to minimize project risk. Maintaining inventory buffers, ordering well in advance, and monitoring news on pipeline material trends are strategies proven to help teams navigate these challenges.

Innovation and Technology in Piping Supply

The deployment of technology in the piping industry has transformed procurement, inventory management, and even asset performance tracking. Utilizing digital barcoding, Internet of Things (IoT) sensors, and automated inventory platforms reduces inefficiencies and allows for real-time asset tracking—a particularly valuable shift for both large infrastructure projects and smaller residential installations. Companies that embrace data analytics and digital platforms stay more agile and can react quickly to shifts in demand or supply availability. Forward-thinking businesses should monitor how these tools are changing global operations and reshaping standard industry practices. Emerging trends include remote monitoring, predictive maintenance, and direct integration of procurement data to streamline communication and reduce costly errors. Wired offers a comprehensive discussion of these tech trends.

Sustainable Practices and Environmental Trends

Environmental concerns are now central to piping supply decisions. Manufacturers and suppliers are increasingly judged on their energy use, emissions, and recycling practices. Programs to capture and repurpose manufacturing offcuts or to invest in renewable production facilities are more common, making sustainability not just a regulatory requirement but a competitive differentiator. Small shifts—such as sourcing locally to reduce transport emissions or using piping systems designed for easy end-of-life recycling—translate into meaningful impacts for corporate responsibility and project certification. As sustainability expectations rise, documenting green practices and verifying product origins will be standard across public and private sector projects.

Training, Certification, and Safety

Comprehensive training and certification have grown beyond simple installation techniques. Today’s workforce requires knowledge of evolving regulations, new joining technologies, and advanced diagnostic tools. Ongoing education builds in-house expertise and cultivates strong, safe work habits, supporting both streamlined project execution and reduced liability for employers. Industry certifications also help teams keep abreast of rapidly changing products and methodologies, reinforcing best practices that avoid costly mistakes and enhance reputation.

Planning and Risk Management for Large Projects

Complexity accelerates in large-scale projects, making thorough risk management and planning an absolute necessity. Industry leaders recommend establishing detailed project schedules, supply audits, and open communication with vendors to identify bottlenecks before they occur. Analyzing the potential impact of global market shifts, tariffs, and logistical challenges helps teams anticipate disruption and create contingency plans. Integration of digital project management tools, regular vendor strategy sessions, and risk scenario planning have all become industry standards for successfully completing projects on time and on budget.

Looking Ahead: Adaptation for the Future

The future of piping supply promises ongoing opportunities for those ready to embrace change, leverage cutting-edge technology, and prioritize eco-friendly practices. Regular engagement with the latest industry news and active networking puts forward-thinking companies in positions of strength. Staying flexible and committed to continuous improvement assures the adaptability needed to remain resilient against ongoing and emerging challenges in this vital sector.